Maintenance of road tankers, storages and pumps for cryogenic gases

The work carried out by A.L.Cryo on cryogenic tanks and storages covers all customer requirements and ranges from the installation of ship’s lashing hooks, to revamping, to more complex and customized work, always and in any case in full compliance with regulations.

Interventions that A.L.Cryo can carry out on Cryogenic Tanks and road tankers:

Periodical revision with Notified Body

Reassessment of conformity according to the TPED Directive

Revamping old tanks/storages

Transfer/Installation of tanker on new trailer

Repair of tanks/storages

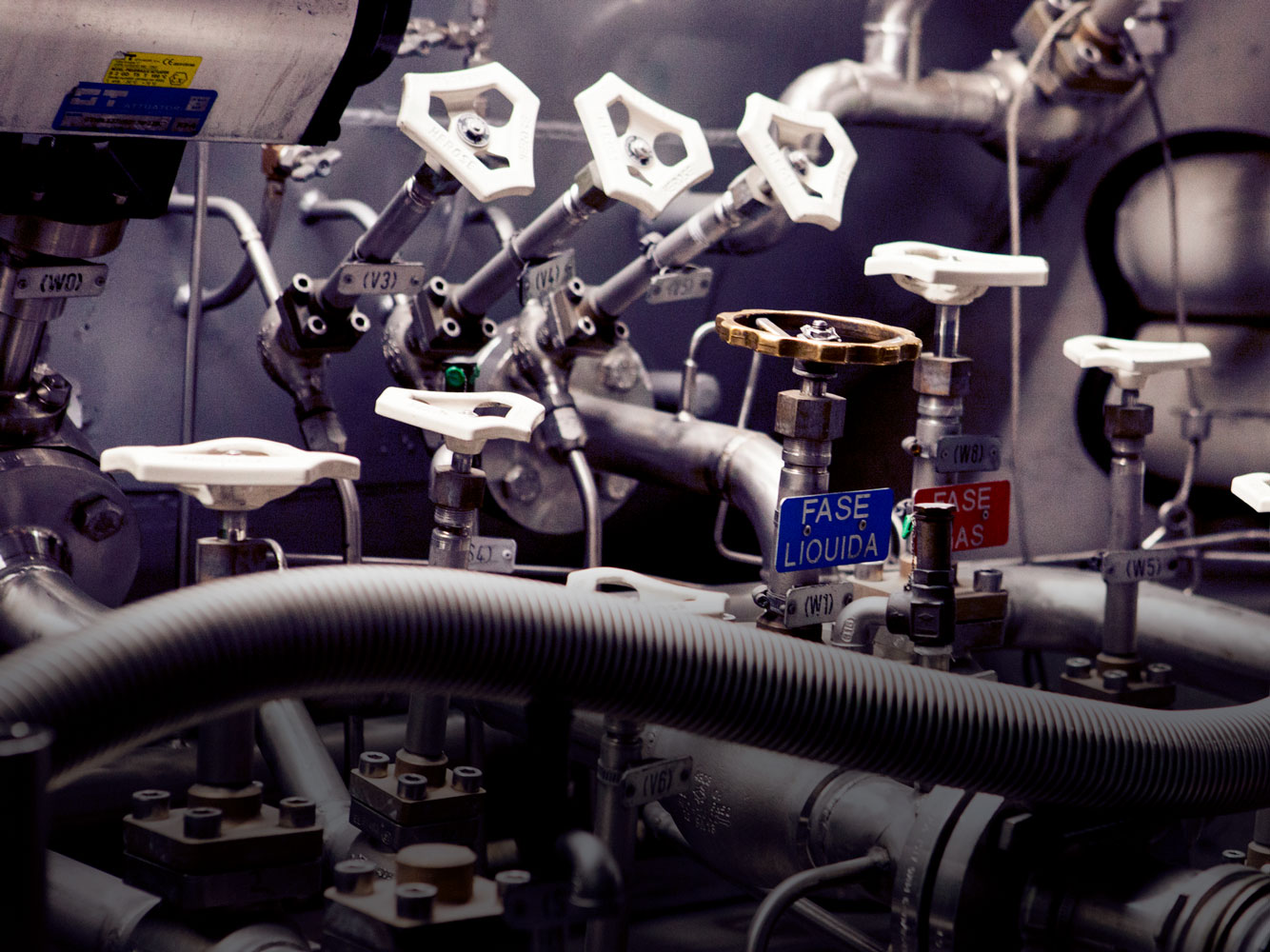

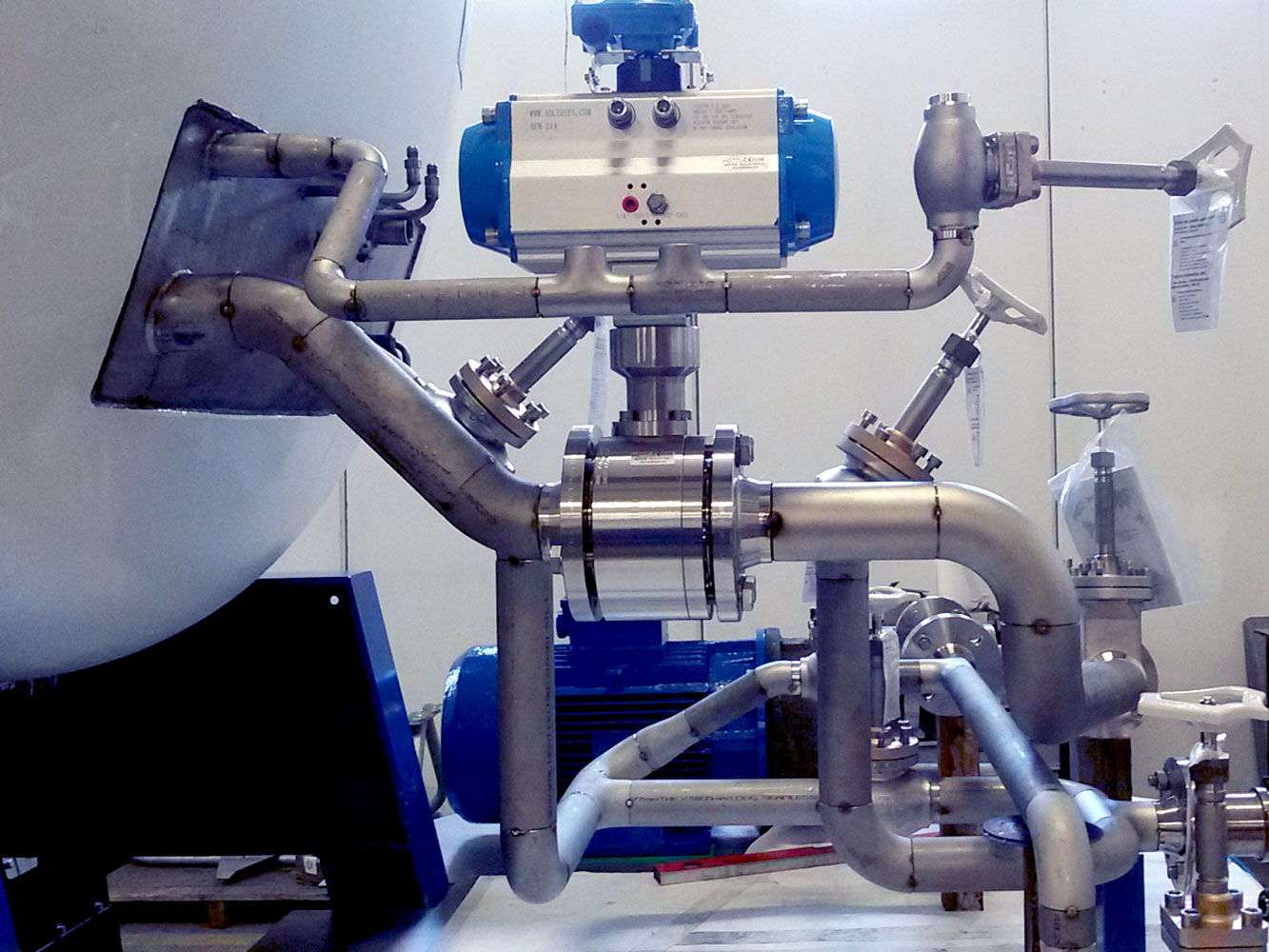

Realization of new piping

Installation of pumps/generators

Construction/installation of electrical panels

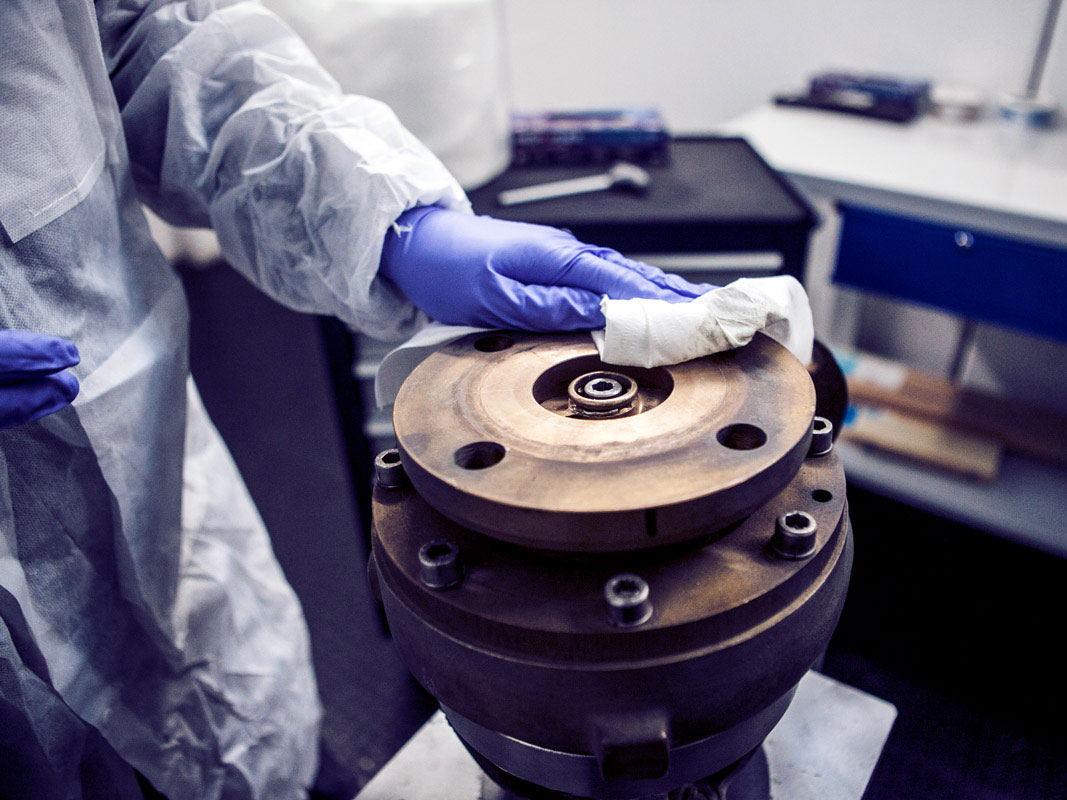

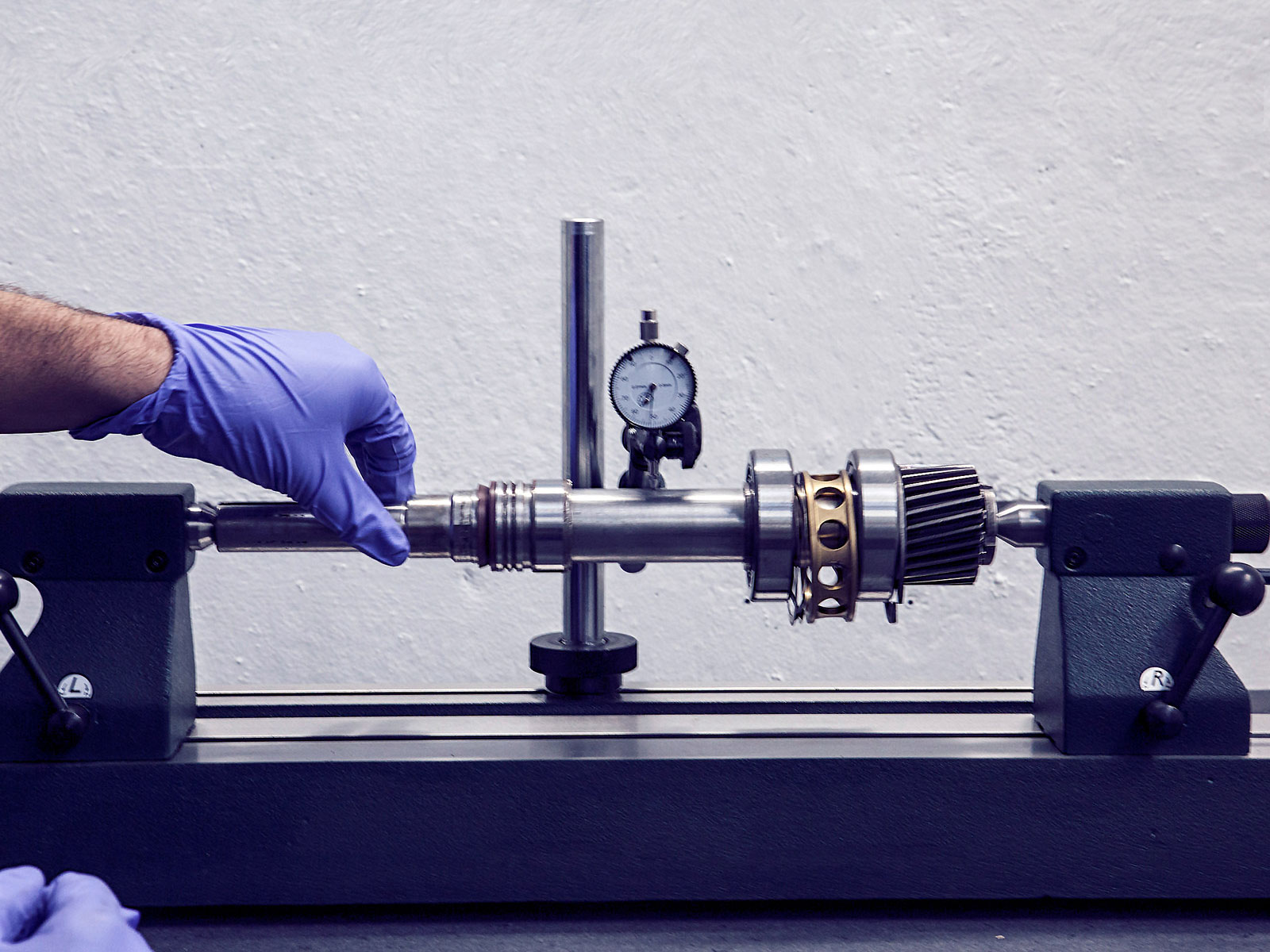

Maintenance (Checks and Mechanical repairs on rolling stock and bodywork parts – Cryogenic pumps – Shunting valves – Evaporators – Hose pipes etc.).

Varnishing and Applying Company trademarks and logos

Vacuum Check/Reset with Rotative/Roots pumps and helium leak detector

Verification/calibration of safety valves on special test benches with certified pressure gauges

Non Destructive Checks, including radiographic checks

Transfer hose check

Complete maintenance of cryogenic pumps